LIGHT UP YOUR PICKING,

KITTING & ASSEMBLY.

AT AUTOMATE BOOTH 4723

Visit Matthews’ booth 4723 during AUTOMATE 2024 to see Lightning Pick demonstrate light-directed picking, kitting and assembly modes, and how the scalable platform can be integrated into PC or PLC-managed automation environments.

Trusted Solution Partner

Thousands of Systems Deployed Worldwide

Proven Interfaces

Tier 1 WMS and MHE Integration Expertise

Flexible Applications

Modular, Scalable Systems Evolve with Needs

Advanced Software

Complete, Real-Time System Visibility & Control

WAREHOUSE AUTOMATION BRANDS

WAREHOUSE EXECUTION SYSTEMS

Matthews’ Pyramid and Compass software and controls solutions integrate interconnected systems to balance work, provide process visibility and boost end-to-end material flow with continuous measurements, holistic system analysis, workload orchestration and more to enhance order flow, volume, and speed.

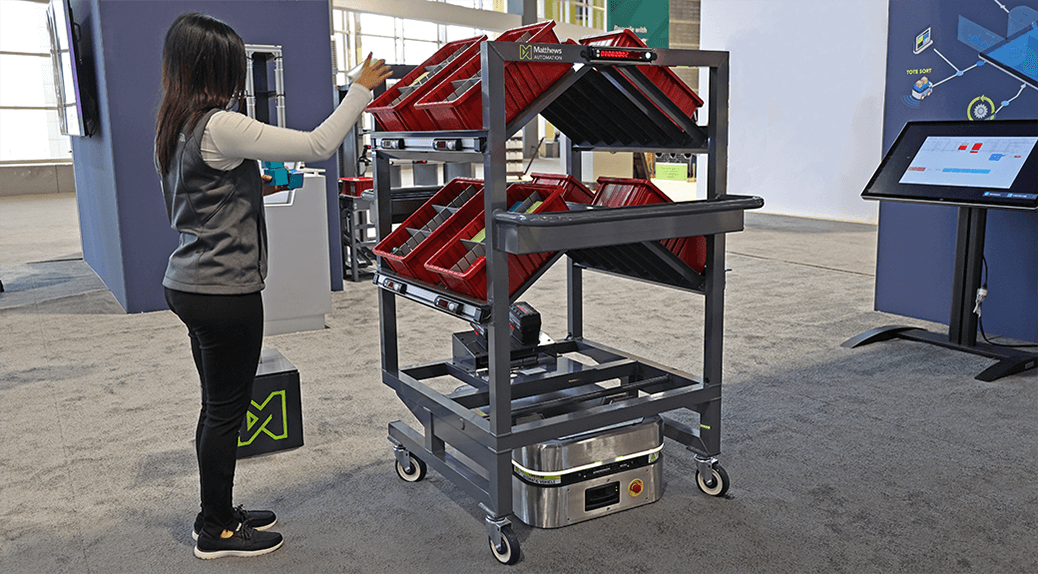

LIGHT-DIRECTED SYSTEMS

Matthews’ Lightning Pick suite of light-directed material handling applications energize omnichannel order fulfillment speed, accuracy and efficiency with advanced pick-to-light, put-to-light and put walls, pack-to-light for store replenishment, automated mobile picking carts and other paperless picking systems.

INDUSTRY INSIGHTS

New Blog: Five Technologies to Learn about at MODEX 2024

AUTOMATION INSIGHTS

Matthews Automation features the latest advances in automation technology at MODEX 2024, Booth B1013.

New Blog: Meet me at MODEX; Meet the Matthews Automation team

AUTOMATION INSIGHTS

Meet some of the wonderful staff working our MODEX 2024, booth #B1013.

CONTROL SYSTEMS

CONVEYOR AND SORTER CONTROLS

Matthews Automation furnishes complete control systems for large conveying, sortation systems and automated equipment to optimize flow, increase accuracy, decrease order cycle times and improve productivity in distribution centers. Our Pyramid and Compass controls solutions have been leveraged for both new installations and to retrofit existing material handling equipment to optimize efficiency and performance.

Matthews is a Rockwell Gold System Integrator Partner

Matthews Automation provides solutions based upon Allen-Bradley/Rockwell PLC platforms and is a Gold level system integrator partner. We offer an extensive suite of pre-engineered, robust, reliable and time-tested programmable logic controller (PLC)-based applications and provide turnkey material handling equipment (MHE) control solutions.

To learn more about our Pyramid controls experience and Rockwell Automation partnership, read here.

INFORMATION ANYWHERE

Matthews Automation’s first Web-based front-end WES, NEXUS

The NEXUS Warehouse Execution Systems’ all-new, web-based front end delivers an intuitive, configurable workspace with complete system visibility and control. Now users can access NEXUS on all devices – from PCs to tablets to phones – regardless of operating system.

CLOUD-BASED SOLUTIONS

Designed for reliability and security

Based on over 30 years of experience developing computerized order fulfillment systems, Matthews has implemented software in all types of companies, primarily for major brands in the distribution, logistics and warehousing industries, as well as manufacturers. Matthews Automation’s cloud-based software solutions make data available in real time from anywhere.

Matthews Automation Solutions is a Matthews International company

Matthews International Corporation (NASDAQ GSM: MATW) is a global provider of brand solutions, memorialization products and industrial technologies. The Industrial Technologies segment designs, manufactures, services and distributes high-tech custom energy storage, marking, coding and industrial automation technologies and solutions. The SGK Brand Solutions segment is a leading provider of packaging solutions and brand experiences, helping companies simplify their marketing, amplify their brands and provide value. The Memorialization segment is a leading provider of memorialization products, including memorials, caskets and cremation and incineration equipment, primarily to cemetery and funeral home customers that help families move from grief to remembrance. The Company has approximately 11,000 employees in more than 26 countries on six continents that are committed to delivering the highest quality products and services.