With displays in both the Discovery Center and new Robotics Experiential Area, Manhattan Associates’ customers can explore the latest light-directed, “Fulfillment Forward” solutions.

At the 2019 Manhattan Momentum Conference, Matthews Automation Solutions and its Lightning Pick brand will showcase “Fulfillment Forward” solutions in two separate areas throughout the event, held May 20-23, 2019 at the JW Marriott Phoenix Desert Ridge Resort and Spa in Phoenix, Arizona.

At the 2019 Manhattan Momentum Conference, Matthews Automation Solutions and its Lightning Pick brand will showcase “Fulfillment Forward” solutions in two separate areas throughout the event, held May 20-23, 2019 at the JW Marriott Phoenix Desert Ridge Resort and Spa in Phoenix, Arizona.

In the Discovery Center, Pete Gerbitz, System Sales Manager, will be on hand to discuss a variety of projects that combine Lightning Pick’s light-directed fulfillment systems with Manhattan Associates’ software. Included are pick-to-light, put-to-light, pick-to-cart and pick-to-pack solutions built on the Lightning Pick’s proven, eponymous material handling software that easily interfaces with warehouse management systems (WMS) from all major vendors. Installations span a variety of industries and market verticals, including omni-channel and e-commerce retail order fulfillment, third-party logistics (3PLs), pharmaceuticals, health and beauty, and more.

Additionally, Matthews’ self-navigating Autonomous Mobile Robot (AMR) will be showcased in the Momentum Conference’s new Robotics Experiential Area. Offered with a variety of different attachment options that address multiple fulfillment-related applications—including materials movement and picking assistance—the featured Matthews’ AMR will be equipped with a cluster picking attachment.

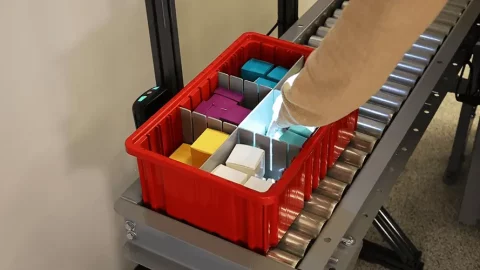

The light-directed picking attachment carries multiple totes or shipping cartons, enabling the AMR to boost picking productivity and throughput by optimizing zone, batch and cluster picking without the need for conveyors, sleds or picking carts. The bots transport the order totes while the operators make picks within their zones. Each tote may represent a specific customer, store or department within a store. To start the process, the robot positions itself in an active pick zone for easy operator access. Pick-to-light or put-to-light modules direct the operator to the next stock keeping unit (SKU) required for picking.

Simultaneously, lights on the AMR’s cluster picking attachment illuminate under each container requiring that item and indicate the quantity needed of that SKU. The operator completes the picks/puts and presses the task complete button to tell the software the task is finished. The bot travels to the next required SKU for the order and the process repeats until all picks in that zone are complete. The AMR then moves to another zone for additional picks as required by the order set.

Once all picks are complete, the bot navigates its picked cartons to pack-out stations for order consolidation, packaging and shipment. Meanwhile, other AMRs continue to work with operators in their picking zones and the pickers continue to work, uninterrupted. This synchronized interaction between pick and put systems, robots and operators enables employees to concentrate on their core task—order picking.

“These bots complement more traditional material handling automation, such as picking systems, put walls and warehouse execution software,” explains Dave Remsing, Vice President of Market Development for Matthews Automation Solutions. “They can either augment conveyor, carts and sleds, or provide a more agile pick routing alternative. By delivering more integrated, end-to-end automation, Matthews AMR-assisted applications enable users to achieve higher levels of productivity.”

Traveling autonomously throughout an operation, the Matthews AMR uses natural feature navigation (also known as contour or landmark navigation). It deploys 2D laser scanning of fixed points within the environment, mapping its path instead of utilizing reflectors, tape or other targets to maneuver. This function enables the robot to be a quick, low-cost solution that easily accommodates physical changes in the facility layout (unlike target-based systems that need new reflective marks located, fixed and surveyed to adapt to operational modifications). Its ability to avoid obstacles and self-determine its own route also makes the Matthews AMR ideal for more dynamic warehouse and manufacturing facilities.

Additionally, Dr. Paul Rivers, Managing Director for Matthews Automation Solutions’ Guidance Automation brand, will be a presenter at Momentum’s “The Robot Revolution is Here” Power Session on Tuesday, May 21 from 10:30 – 11:20 a.m. Guidance is a leading provider of autonomous vehicle and robot technologies. Paul and his co-presenters will discuss how the new generation of robots, integrated with Manhattan WMS, are redefining modern warehouses.

For more information, contact Lynn Drewicz, Marketing Manager, Matthews Automation Solutions at [email protected], 262.250.2169, or visit matthewsautomation.com.

# # #

ABOUT MATTHEWS AUTOMATION SOLUTIONS

Matthews Automation Solutions—a division of Matthews International Corporation—provides integrated hardware and software solutions that streamline processes, boost throughput and solve global supply challenges for manufacturers and distributors worldwide. For automation challenges in manufacturing, packaging, fulfillment or distribution, Matthews’ combined expertise delivers the integrated solution that meets an organization’s needs today, and grows with them tomorrow. It includes leading warehouse automation brands Lightning Pick, Compass Engineering and Pyramid.